In a world where environmental concerns are gaining increasing attention, Shree Water Tech stands at the forefront, providing cutting-edge effluent treatment solutions to tackle the challenges posed by industrial wastewater.

We take immense pride in our ability to design, commission, and maintain an array of effluent treatment systems that cater to the diverse needs of industries such as automobiles, chemicals, distilleries, beverage bottling units, dairy, breweries, refineries, paper & pulp, and mining. In this article, we will explore the critical aspects of effluent treatment, its significance in an era of water scarcity, and how Shree Water Tech is leading the way as a premier Effluent Treatment Plant (ETP) manufacturer and supplier in India.

Effluent Treatment: A Sustainable Solution

Effluent treatment is a crucial process that involves the purification of industrial wastewater to ensure it meets environmental standards. Industries, including those engaged in the production of medicines, leather, textiles, and chemicals, rely on effluent treatment to comply with government regulations on pollution emissions. This not only helps industries maintain a clean and green working environment but also reduces their reliance on freshwater sources for various processes.

Key Processes in Effluent Treatment

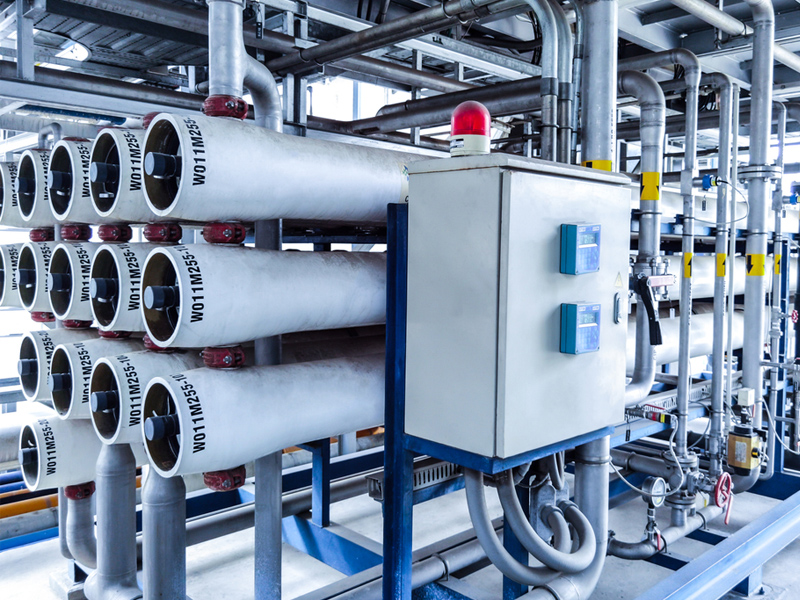

Effluent Treatment Plants (ETPs) like those provided by Shree Water Tech are instrumental in treating a wide range of pollutants found in industrial wastewater. These pollutants can include organic and inorganic matter, oil, grease, heavy metals, suspended particles, and more. ETPs are designed to facilitate various treatment processes, including physical, chemical, membrane, and biological methods, ensuring that the effluent water is treated effectively and made safe for consumption or reuse.

Promoting Water Recycling and Resource Optimization

As the global water crisis looms larger, industries are increasingly seeking to recycle and reuse treated effluents. Shree Water Tech is at the forefront of this eco-friendly initiative by offering effluent treatment solutions that incorporate advanced technologies like reverse osmosis and ultra-filtration systems. These tertiary treatment processes make it possible for industries to recycle water for various applications, reducing their overall water consumption and contributing to resource optimization.

Shree Water Tech's Commitment to Quality

At Shree Water Tech, we take immense pride in our commitment to providing top-notch effluent treatment solutions. Our dedicated team of qualified and experienced professionals works tirelessly to offer round-the-clock technical support to our customers, ensuring their utmost satisfaction. This level of service has earned us the trust of our customers and propelled us to thrive in the competitive water treatment industry. We aim to make water treatment a sophisticated, scientific, and customer-friendly business, and our commitment to matchless product quality, prompt services, and on-time delivery has fueled our rapid growth.

Customized Effluent Treatment Solutions

Shree Water Tech's effluent treatment plants strictly adhere to the design specifications mandated by regulatory authorities. Our customized systems are engineered to suit a wide range of effluents and maintain high efficiency. We offer physico-chemical and biological treatments, along with cost-effective hydrophilic membrane technologies, to enhance efficiency and environmental compliance for industries.

In a world where environmental responsibility and resource optimization are paramount, Shree Water Tech is your trusted partner in effluent treatment solutions. With our state-of-the-art Effluent Treatment Plants and a commitment to quality and sustainability, we are dedicated to helping industries across India and beyond meet their wastewater treatment needs. Shree Water Tech, the premier Effluent Treatment Plant manufacturer, exporter, and supplier, is your key to a cleaner, greener, and more sustainable future.

What is an Effluent Treatment Plant?

An Effluent Treatment Plant (ETP) is a specialized facility designed to treat and purify industrial wastewater, ensuring it meets environmental standards and regulations. ETPs employ a range of physical, chemical, membrane, and biological processes to remove pollutants such as organic and inorganic matter, oil, grease, heavy metals, and suspended particles from the effluent water. This treatment process not only safeguards the environment by preventing water pollution but also facilitates the recycling and reutilization of treated effluents, making it an essential component for industries aiming to reduce their environmental footprint and water consumption.

How to Treat Effluent Water?

Treating effluent water involves a multifaceted approach to ensure its purification and compliance with environmental standards. The process typically includes physical, chemical, membrane, and biological treatments. Initially, physical methods like sedimentation and filtration are employed to remove larger particles and impurities. Then, chemical treatments use coagulants and flocculants to precipitate contaminants. Membrane processes such as reverse osmosis and ultra-filtration are applied for finer purification, and finally, biological treatments utilize microorganisms to break down organic matter. This comprehensive treatment regimen ensures that effluent water is cleansed of pollutants, making it safe for discharge, recycling, or reuse, while contributing to environmental sustainability and responsible water management.

Effluent treatment plant process

The effluent treatment plant (ETP) process is a series of meticulously orchestrated steps to cleanse and purify industrial wastewater. It begins with the screening and removal of large debris, followed by chemical coagulation to bind impurities and create flocs that can be easily separated. The effluent then undergoes sedimentation to further remove solids. Subsequently, biological treatment employs beneficial microorganisms to break down organic matter. Membrane filtration or advanced techniques like reverse osmosis are employed to remove remaining contaminants. The clarified water is disinfected, ensuring it meets environmental standards, before either being safely discharged or recycled for industrial use, thus promoting responsible water management and environmental sustainability.

Why Shree Water Tech is the Top effluent treatment plant manufacturer and supplier in Pune, India

Shree Water Tech has solidified its reputation as the top effluent treatment plant manufacturer and supplier in Pune, India, through a combination of unwavering commitment to quality, cutting-edge technology, and customer-centric approach. Their customized effluent treatment solutions strictly adhere to regulatory standards, ensuring the efficient purification of industrial wastewater. Shree Water Tech's dedicated team of experts provides round-the-clock technical support, fostering the utmost customer satisfaction. With a focus on delivering matchless product quality, prompt services, and on-time delivery, Shree Water Tech has rapidly grown to excel in the water treatment industry, making it the preferred choice for businesses seeking sustainable, efficient, and reliable effluent treatment solutions.

Together, let's make a positive impact on the environment and promote sustainable water management practices.